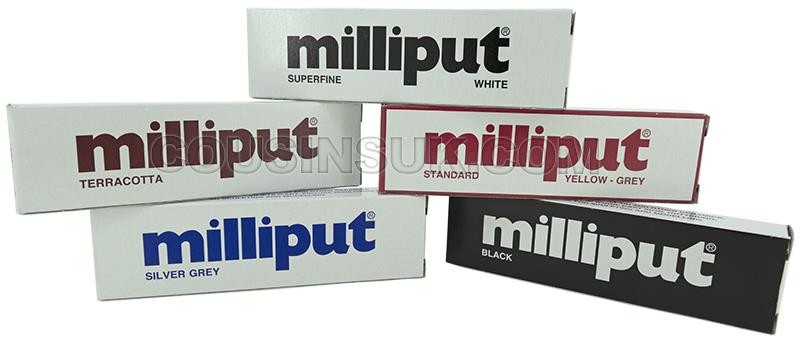

We pride ourselves on that our products are manufactured and distributed from our premises in Wales to over 35 countries worldwide. Milliput remains a family run company committed to manufacturing a high quality product. To learn more about how and for what purposes Amazon uses personal information (such as Amazon Store order history), please visit our Privacy Notice. I, Michael Wihart, confirm that the work presented in this thesis is my own. Established in 1968, Milliput is one of the world's leading producers of epoxy putties. You can change your choices at any time by visiting Cookie Preferences, as described in the Cookie Notice. 127 Mediterranean Sea 155 metallics 25 Metropolis 2 Meyers, Michael 201, 203 Miami Seaquarium 130 Milliput putty 13, 19 Ming the Merciless 222, 223. Great for sculpting, bonding, embellishing. Click ‘Customise Cookies’ to decline these cookies, make more detailed choices, or learn more. Aves Apoxie Sculpt combines the features and benefits of sculpting clay with the adhesive power of epoxy. Third parties use cookies for their purposes of displaying and measuring personalised ads, generating audience insights, and developing and improving products. The Part A resin component of most 2-part polyurethane resins comes with a certain amount of filler already included. This includes using first- and third-party cookies, which store or access standard device information such as a unique identifier. Superfine White Milliput is specially formulated for the restoration of porcelain and ceramics where a fine finish. If you agree, we’ll also use cookies to complement your shopping experience across the Amazon stores as described in our Cookie Notice. We also use these cookies to understand how customers use our services (for example, by measuring site visits) so we can make improvements. Their son Stephen joined the business in 2006.We use cookies and similar tools that are necessary to enable you to make purchases, to enhance your shopping experiences and to provide our services, as detailed in our Cookie Notice. Jack and Lena retired from the business and handed over the running of the company to their son Eddie and his wife Jane, successfully maintaining the 'family' stamp on the Company for the future. In 1991 The Milliput Company received official recognition of their efforts with a prestigious ‘Rural Enterprise Award’ from the Development Board for Rural Wales. Black Milliput went into production in 2007 for restorers working with marble, slate, ceramics, cast iron and ebonised wood. rough up the surface of the plastic a bit.

Demand for other colours continued and in 1992 Terracotta Milliput was introduced for the repair of terracotta pots, urns, brickwork, quarry tiles etc. Michael Hatch has used the PART sets to great effect on a Revell Tiger kit. For major filling or body modifications, a two-part putty like Milliput is the preferred option.

However, the pressure was on for a ‘pure white’ putty and Superfine White Milliput followed in 1983 becoming instantly popular for restorers and, once again, another great success for the Company. Section 1 Introduction (edited by Michael Kelly). Silver Grey Milliput was formulated and a little market research revealed military modellers liked the new colour too.

In 1982 porcelain restorers using Milliput in their work requested a white putty which would suit their needs more readily than the Standard (Yellow/Grey) grade that launched the Company. In 1979 Lena and Jack moved The Milliput Company to larger premises in Dolgellau, Mid Wales which enabled the product to be developed further. Both amateurs and professionals have come to rely on Milliput for the production of superbly detailed and refined miniatures.

It was during 1970 that modellers worldwide soon began adopting Standard (Yellow/Grey) Milliput to fill gaps in metal models, converting stock figurines, making buildings and scenic base work and for the production of master models for commercial purposes. Standard (Yellow/Grey) Milliput was the first grade produced which, when equal quantities were mixed together, cured to a hard finish and then could be sanded, drilled, filed, moulded, turned and painted. In 1968 Jack and Lena Rickman founded The Milliput Company to manufacture a two-part epoxy putty for Industry and DIY markets.

0 kommentar(er)

0 kommentar(er)